What is a Circuit Board?

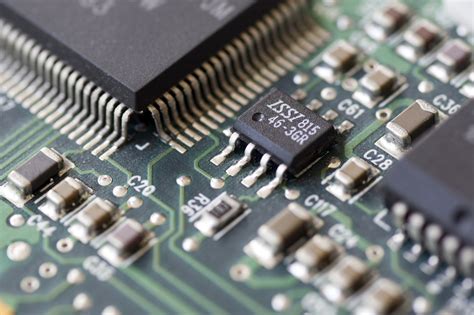

A circuit board, also known as a PCB, is a flat insulating board that holds and connects electronic components using conductive pathways, tracks, or signal traces etched from copper sheets laminated onto a non-conductive substrate. In simpler terms, a PCB is a thin board made of fiberglass or other composite material that has copper tracks printed on it to connect various electronic components.

Types of Circuit Boards

There are several types of circuit boards, each designed for specific applications and manufacturing processes. The most common types include:

- Single-sided PCBs

- Copper traces are printed on one side of the board

- Used in simple, low-cost electronics

- Double-sided PCBs

- Copper traces are printed on both sides of the board

- Allows for more complex designs and higher component density

- Multi-layer PCBs

- Consists of multiple layers of copper traces separated by insulating material

- Used in high-performance electronics that require high component density and complex connectivity

- Flexible PCBs

- Made from flexible materials like polyimide

- Can bend and conform to various shapes

- Used in applications where flexibility and space constraints are important

- Rigid-Flex PCBs

- Combines rigid and flexible PCBs

- Allows for three-dimensional designs and improved reliability

| PCB Type | Layers | Applications |

|---|---|---|

| Single-sided | 1 | Simple, low-cost electronics |

| Double-sided | 2 | More complex designs, higher component density |

| Multi-layer | 3+ | High-performance electronics, complex connectivity |

| Flexible | 1+ | Applications requiring flexibility and space constraints |

| Rigid-Flex | 2+ | Three-dimensional designs, improved reliability |

How Does a PCB Work?

A PCB works by providing a platform for electronic components to be mounted and connected. The copper tracks on the PCB act as wires, allowing electrical signals to travel between components. The non-conductive substrate provides insulation and mechanical support for the components and tracks.

PCB design Process

The PCB design process typically involves the following steps:

- Schematic Design

- Create a schematic diagram of the electronic circuit

- Specify component values and connections

- Board Layout

- Determine the physical placement of components on the PCB

- Route the copper tracks to connect components according to the schematic

- Fabrication

- Manufacture the PCB based on the designed layout

- Involves processes like etching, drilling, and plating

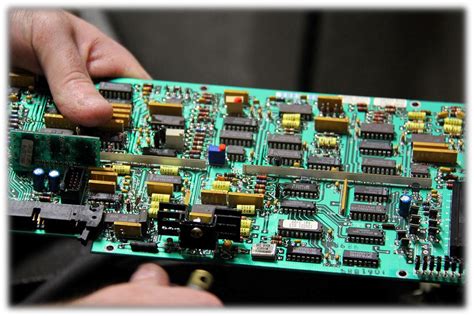

- Assembly

- Solder electronic components onto the fabricated PCB

- Perform quality control and testing

PCB Components

A PCB can hold various types of electronic components, including:

- Resistors

- Capacitors

- Inductors

- Diodes

- Transistors

- Integrated Circuits (ICs)

- Connectors

- Switches

- LEDs

These components work together to perform specific functions within the electronic device.

Importance of PCBs in Electronics

PCBs have revolutionized the electronics industry by providing a standardized and efficient way to design and manufacture electronic devices. Some of the key benefits of using PCBs include:

- Miniaturization

- PCBs allow for the compact arrangement of electronic components

- Enables the development of smaller, more portable devices

- Reliability

- Copper tracks on PCBs provide a stable and reliable means of connecting components

- Reduces the risk of loose connections and short circuits

- Mass Production

- PCBs are designed for automated manufacturing processes

- Allows for the efficient production of large quantities of electronic devices

- Cost-effectiveness

- Standardized PCB design and manufacturing processes reduce production costs

- Makes electronic devices more affordable for consumers

Applications of PCBs

PCBs are used in a wide range of electronic devices and industries, including:

- Consumer electronics (smartphones, computers, televisions)

- Automotive electronics (engine control units, infotainment systems)

- Medical devices (patient monitors, imaging equipment)

- Industrial automation (process control systems, robotics)

- Aerospace and defense (avionics, communications systems)

- Internet of Things (IoT) devices (smart home appliances, wearables)

The versatility and reliability of PCBs have made them an indispensable part of modern technology.

Frequently Asked Questions (FAQ)

- What is the difference between a PCB and a breadboard?

-

A PCB is a permanent, custom-designed board that holds and connects electronic components using copper tracks. A breadboard, on the other hand, is a temporary prototyping tool that allows for the quick assembly and testing of electronic circuits without soldering.

-

Can PCBs be repaired if damaged?

-

In some cases, PCBs can be repaired if the damage is localized and not too extensive. Common repair techniques include soldering, wire jumpers, and conductive epoxy. However, it is often more cost-effective to replace the entire PCB if the damage is severe or if the device is under warranty.

-

How long do PCBs last?

-

The lifespan of a PCB depends on various factors, such as the quality of the materials used, the manufacturing process, and the operating environment. In general, a well-designed and manufactured PCB can last for several years or even decades, provided it is not subjected to excessive stress or harsh conditions.

-

What is the environmental impact of PCBs?

-

The production and disposal of PCBs can have negative environmental impacts if not handled properly. Some of the materials used in PCBs, such as lead and certain flame retardants, can be harmful to human health and the environment. To mitigate these impacts, many countries have implemented regulations on the use of hazardous substances in electronics and have established recycling programs for e-waste.

-

What is the future of PCB technology?

- The future of PCB technology is driven by the increasing demand for smaller, faster, and more efficient electronic devices. Some of the emerging trends in PCB design and manufacturing include the use of advanced materials (e.g., graphene, ceramic), embedded components, and 3D printing. Additionally, the growth of the Internet of Things (IoT) and the development of 5G networks are expected to drive innovation in PCB technology to support high-speed, low-latency, and high-bandwidth applications.

In conclusion, PCBs are the unsung heroes of the electronics world, providing the foundation for the devices we rely on every day. By understanding what a PCB is, how it works, and its importance in electronics, we can better appreciate the technological marvels that surround us and the role of PCBs in enabling these advancements.

Leave a Reply