Introduction to PCB Material Pricing

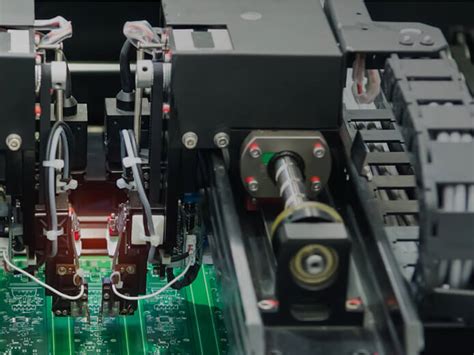

Printed Circuit Boards (PCBs) are essential components in modern electronic devices, ranging from smartphones and computers to industrial equipment and aerospace systems. The cost of producing PCBs is heavily influenced by the materials used in their construction. In this article, we will dive deep into the world of PCB material pricing, exploring the factors that affect the cost and providing insights into the current market trends.

Factors Influencing PCB Material Prices

Several key factors contribute to the overall cost of PCB materials:

Raw Material Costs

The primary raw materials used in PCB production include copper, fiberglass, and epoxy resin. The prices of these commodities can fluctuate based on global supply and demand, as well as geopolitical events and economic conditions.

Manufacturing Processes

The complexity of the PCB manufacturing process also impacts material costs. Advanced techniques, such as high-density interconnect (HDI) and multilayer boards, require more sophisticated materials and equipment, resulting in higher prices.

Industry Standards and Certifications

PCBs used in specific industries, such as aerospace and defense, must meet stringent quality and reliability standards. Materials that comply with these standards often come at a premium price.

Supply Chain Dynamics

The global nature of the PCB industry means that material prices can be affected by supply chain disruptions, tariffs, and trade agreements between countries.

Types of PCB Materials and Their Prices

PCBs can be manufactured using a variety of materials, each with its own unique properties and price points. Let’s explore some of the most common PCB materials:

FR-4

FR-4 is the most widely used PCB material, known for its excellent electrical insulation properties and mechanical strength. It is a composite material made of woven fiberglass cloth with an epoxy resin binder. The average price of FR-4 laminate ranges from $0.10 to $0.30 per square inch, depending on the thickness and copper weight.

| Thickness (mm) | Copper Weight (oz) | Price Range (per sq. inch) |

|---|---|---|

| 0.8 | 1 | $0.10 – $0.15 |

| 1.6 | 1 | $0.15 – $0.20 |

| 2.4 | 2 | $0.20 – $0.30 |

High-Tg FR-4

High-Tg FR-4 is a variant of the standard FR-4 material, designed to withstand higher temperatures. This makes it suitable for applications that require lead-free soldering or exposure to extreme environments. High-Tg FR-4 is typically 20-30% more expensive than standard FR-4.

Polyimide

Polyimide is a high-performance polymer known for its excellent thermal stability, chemical resistance, and mechanical strength. It is often used in applications that demand reliability under harsh conditions, such as aerospace and military electronics. Polyimide PCBs can cost 2-3 times more than FR-4 boards.

PTFE (Teflon)

PTFE, or Polytetrafluoroethylene, is a fluoropolymer with exceptional dielectric properties and low dissipation factor. It is commonly used in high-frequency applications, such as radar and wireless communication systems. PTFE PCBs are among the most expensive, with prices ranging from $5 to $20 per square inch.

| Material | Price Range (per sq. inch) |

|---|---|

| FR-4 | $0.10 – $0.30 |

| High-Tg FR-4 | $0.13 – $0.39 |

| Polyimide | $0.30 – $0.90 |

| PTFE | $5.00 – $20.00 |

Current Market Trends in PCB Material Pricing

The PCB industry is constantly evolving, driven by advancements in technology and changes in consumer demand. Here are some of the current market trends influencing PCB material prices:

Miniaturization and High-Density Interconnect (HDI)

As electronic devices become smaller and more powerful, there is a growing demand for compact, high-density PCBs. This trend has led to an increased use of HDI technology, which requires advanced materials and manufacturing processes. As a result, the prices of HDI-compatible materials, such as thin laminates and micro-via materials, have been on the rise.

5G and High-Frequency Applications

The rollout of 5G networks and the expansion of high-frequency applications have driven the demand for PCB materials with superior dielectric properties, such as PTFE and low-loss laminates. The increased demand for these specialized materials has put upward pressure on their prices.

Environmental Regulations and Green Initiatives

Governments and industry organizations worldwide are implementing stricter environmental regulations and promoting green initiatives. This has led to a growing demand for eco-friendly PCB materials, such as halogen-free and lead-free laminates. These materials often come at a higher price compared to their traditional counterparts.

Strategies for Optimizing PCB Material Costs

While PCB material prices can significantly impact the overall cost of production, there are several strategies that manufacturers and designers can employ to optimize expenses:

Design for Manufacturability (DFM)

By designing PCBs with manufacturability in mind, designers can reduce the complexity of the production process and minimize the use of expensive materials. This involves optimizing layout, minimizing layer count, and avoiding unnecessary features.

Material Selection

Careful selection of PCB materials based on the specific requirements of the application can help balance cost and performance. For example, using FR-4 instead of polyimide for applications that do not require extreme temperature resistance can result in significant cost savings.

Supply Chain Optimization

Establishing strong relationships with reliable material suppliers and optimizing inventory management can help manufacturers secure competitive pricing and minimize the impact of supply chain disruptions.

Continuous Improvement and Cost Analysis

Regularly reviewing and analyzing material costs, manufacturing processes, and supplier performance can help identify opportunities for cost optimization and drive continuous improvement efforts.

FAQ

What is the most common PCB material?

FR-4 is the most widely used PCB material, known for its excellent electrical insulation properties, mechanical strength, and cost-effectiveness.

Why are PTFE PCBs so expensive?

PTFE PCBs are among the most expensive due to the material’s exceptional dielectric properties and low dissipation factor. These properties make PTFE suitable for high-frequency applications, such as radar and wireless communication systems, which demand superior performance and reliability.

How can I reduce PCB material costs without compromising quality?

To reduce PCB material costs without compromising quality, consider implementing Design for Manufacturability (DFM) principles, carefully selecting materials based on application requirements, optimizing your supply chain, and continuously analyzing costs and processes for improvement opportunities.

Do environmental regulations impact PCB material prices?

Yes, environmental regulations and green initiatives can impact PCB material prices. The growing demand for eco-friendly materials, such as halogen-free and lead-free laminates, often results in higher prices compared to traditional materials.

How does miniaturization trend affect PCB material prices?

The trend towards miniaturization and the use of high-density interconnect (HDI) technology has led to an increased demand for advanced materials, such as thin laminates and micro-via materials. This increased demand has put upward pressure on the prices of these materials.

Conclusion

PCB material prices play a crucial role in determining the overall cost of PCB production. By understanding the factors that influence material prices, the properties and price points of various materials, and the current market trends, manufacturers and designers can make informed decisions to optimize costs while ensuring the desired performance and reliability of their products. Implementing strategies such as Design for Manufacturability, careful material selection, supply chain optimization, and continuous improvement can help navigate the complex landscape of PCB material pricing and maintain a competitive edge in the industry.

Leave a Reply