Types of PCB Materials

There are several types of PCB materials available in the market, each with its own unique properties and applications. The most common PCB materials are:

- FR-4

- Polyimide

- Teflon

- Ceramic

- Aluminum

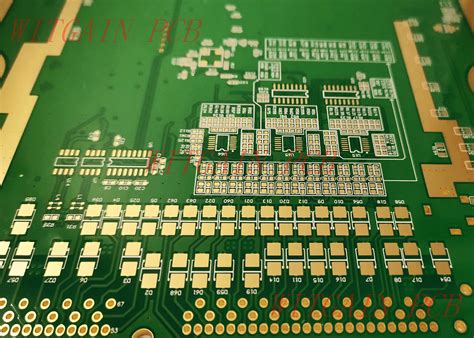

FR-4

FR-4 is the most widely used PCB material. It is a composite material made of woven fiberglass cloth with an epoxy resin binder. FR-4 is known for its excellent mechanical and electrical properties, making it suitable for a wide range of applications.

Properties of FR-4

| Property | Value |

|---|---|

| Dielectric Constant | 4.7 at 1 MHz |

| Dissipation Factor | 0.02 at 1 MHz |

| Thermal Conductivity | 0.29 W/m·K |

| Tg | 130-140°C |

| CTE | 14-16 ppm/°C |

| Flexural Strength | 415 MPa |

| Moisture Absorption | 0.15% |

FR-4 has a relatively high glass transition temperature (Tg), which allows it to withstand high temperatures during soldering and other manufacturing processes. It also has a low coefficient of thermal expansion (CTE), which minimizes thermal stresses and improves reliability.

Applications of FR-4

- Consumer electronics

- Industrial control systems

- Telecommunications equipment

- Automotive electronics

- Medical devices

Polyimide

Polyimide is a high-performance polymer used in PCBs that require high temperature resistance and dimensional stability. It is often used in aerospace, military, and high-end industrial applications.

Properties of Polyimide

| Property | Value |

|---|---|

| Dielectric Constant | 3.5 at 1 MHz |

| Dissipation Factor | 0.002 at 1 MHz |

| Thermal Conductivity | 0.2 W/m·K |

| Tg | 260°C |

| CTE | 12-16 ppm/°C |

| Flexural Strength | 345 MPa |

| Moisture Absorption | 0.4% |

Polyimide has a very high glass transition temperature, allowing it to withstand extreme temperatures. It also has excellent chemical resistance and low moisture absorption, making it suitable for harsh environments.

Applications of Polyimide

- Aerospace and defense

- High-temperature industrial applications

- Automotive electronics

- Medical devices

- Flexible circuits

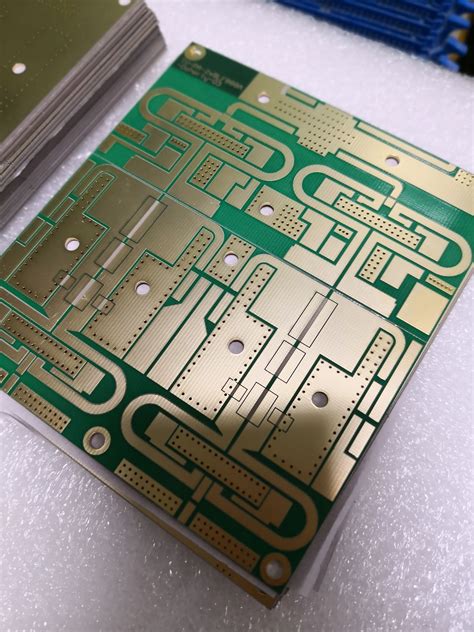

Teflon

Teflon, or Polytetrafluoroethylene (PTFE), is a fluoropolymer known for its low dielectric constant and low dissipation factor. These properties make Teflon an excellent choice for high-frequency and microwave applications.

Properties of Teflon

| Property | Value |

|---|---|

| Dielectric Constant | 2.1 at 1 MHz |

| Dissipation Factor | 0.0002 at 1 MHz |

| Thermal Conductivity | 0.25 W/m·K |

| Tg | 327°C |

| CTE | 100-120 ppm/°C |

| Flexural Strength | 20 MPa |

| Moisture Absorption | <0.01% |

Teflon has an extremely low dielectric constant and dissipation factor, which minimizes signal loss and distortion at high frequencies. However, it has a relatively high CTE and low flexural strength, which can pose challenges during manufacturing.

Applications of Teflon

- High-frequency and microwave circuits

- Radar systems

- Satellite communication equipment

- High-speed digital circuits

- RF and wireless applications

Ceramic

Ceramic PCBs are made from inorganic materials such as alumina or aluminum nitride. They offer excellent thermal conductivity, high dielectric strength, and low dielectric loss, making them ideal for high-power and high-frequency applications.

Properties of Ceramic

| Property | Alumina | Aluminum Nitride |

|---|---|---|

| Dielectric Constant | 9.8 at 1 MHz | 8.8 at 1 MHz |

| Dissipation Factor | 0.0001 at 1 MHz | 0.0005 at 1 MHz |

| Thermal Conductivity | 24-28 W/m·K | 140-180 W/m·K |

| Flexural Strength | 345 MPa | 310 MPa |

| CTE | 6.7 ppm/°C | 4.5 ppm/°C |

| Moisture Absorption | 0% | 0% |

Ceramic PCBs have excellent thermal management properties, making them suitable for high-power applications. They also have a low CTE, which minimizes thermal stresses and improves reliability.

Applications of Ceramic PCBs

- High-power LED lighting

- Automotive power electronics

- High-frequency RF and microwave circuits

- Aerospace and defense

- Medical imaging equipment

Aluminum

Aluminum PCBs consist of an aluminum substrate with a dielectric layer and copper traces. They offer excellent thermal conductivity and heat dissipation, making them ideal for high-power applications that generate significant heat.

Properties of Aluminum PCBs

| Property | Value |

|---|---|

| Dielectric Constant | 4.5 at 1 MHz |

| Dissipation Factor | 0.02 at 1 MHz |

| Thermal Conductivity | 150-200 W/m·K |

| CTE | 23 ppm/°C |

| Flexural Strength | 70 MPa |

| Moisture Absorption | 0% |

Aluminum PCBs have the highest thermal conductivity among all PCB materials, making them excellent for heat dissipation. However, they have a relatively high CTE, which can cause thermal stresses if not properly managed.

Applications of Aluminum PCBs

- Power electronics

- LED lighting

- Automotive electronics

- Motor drives

- High-power industrial applications

Factors to Consider When Choosing a PCB Material

When selecting a PCB material for a specific application, several factors should be considered:

- Electrical properties

- Dielectric constant

- Dissipation factor

- Dielectric strength

- Thermal properties

- Glass transition temperature (Tg)

- Coefficient of thermal expansion (CTE)

- Thermal conductivity

- Mechanical properties

- Flexural strength

- Tensile strength

- Hardness

- Environmental factors

- Operating temperature range

- Humidity resistance

- Chemical resistance

- Manufacturing considerations

- Ease of processing

- Availability

- Cost

By carefully evaluating these factors and understanding the specific requirements of the application, designers can choose the most suitable PCB material to ensure optimal performance, reliability, and cost-effectiveness.

Frequently Asked Questions (FAQ)

-

What is the most commonly used PCB material?

FR-4 is the most widely used PCB material due to its excellent balance of mechanical, electrical, and thermal properties, as well as its cost-effectiveness. -

What PCB material is best for high-frequency applications?

Teflon (PTFE) and ceramic materials like alumina and aluminum nitride are the best choices for high-frequency applications due to their low dielectric constant and low dissipation factor. -

Which PCB material offers the best thermal conductivity?

Aluminum PCBs offer the highest thermal conductivity among all PCB materials, making them ideal for high-power applications that generate significant heat. -

Are polyimide PCBs suitable for high-temperature applications?

Yes, polyimide PCBs are an excellent choice for high-temperature applications due to their high glass transition temperature (Tg) and excellent thermal stability. -

What factors should be considered when choosing a PCB material?

When selecting a PCB material, designers should consider factors such as electrical properties (dielectric constant, dissipation factor), thermal properties (Tg, CTE, thermal conductivity), mechanical properties (flexural strength, tensile strength), environmental factors (operating temperature range, humidity resistance), and manufacturing considerations (ease of processing, availability, cost).

Conclusion

Choosing the right PCB material is crucial for ensuring the optimal performance, reliability, and cost-effectiveness of electronic devices. FR-4 is the most commonly used PCB material due to its excellent balance of properties and cost-effectiveness. However, other materials like polyimide, Teflon, ceramic, and aluminum offer unique advantages for specific applications such as high-temperature, high-frequency, and high-power electronics.

By understanding the properties and applications of different PCB materials and carefully considering the specific requirements of the application, designers can make informed decisions and select the most suitable material for their projects. As technology continues to advance, new PCB materials may emerge to meet the ever-growing demands of the electronics industry.

Leave a Reply