What are PCB Slot Tolerances?

PCB slot tolerances refer to the acceptable range of dimensions for slots or cutouts on a printed circuit board (PCB). These slots are essential for various purposes, such as mounting components, providing clearance for connectors, or allowing access to underlying layers. Maintaining accurate slot tolerances is crucial for ensuring proper fit and function of the PCB in its intended application.

Types of PCB Slots

There are several types of slots commonly found on PCBs:

-

Mounting Slots: These slots are used to secure the PCB to an enclosure or chassis using screws or other fasteners.

-

Connector Slots: These slots provide clearance for connectors, allowing them to pass through the PCB and mate with corresponding components.

-

Access Slots: These slots allow access to underlying layers or components for testing, debugging, or rework purposes.

-

Ventilation Slots: These slots are designed to improve air circulation and heat dissipation, especially in high-power applications.

Factors Affecting PCB Slot Tolerances

Several factors can impact the accuracy and consistency of PCB slot tolerances:

Manufacturing Process

The manufacturing process used to create the slots can significantly influence their tolerances. Common methods include:

-

Punching: A die is used to punch out the slot shape from the PCB material. This method is fast and cost-effective but may result in less precise tolerances compared to other techniques.

-

Routing: A CNC router is used to cut the slot shape into the PCB. This method offers better precision and can handle more complex slot geometries.

-

Laser Cutting: A laser beam is used to cut the slot shape into the PCB. This method provides high precision and can create intricate slot designs, but it may be more expensive than other options.

Material Properties

The properties of the PCB material can also affect slot tolerances:

-

Thickness: Thicker PCBs may be more challenging to machine accurately, leading to wider tolerance ranges.

-

Hardness: Harder PCB materials, such as those used in high-temperature applications, may require specialized tooling and processes to maintain tight tolerances.

-

Laminate Composition: The type and quality of the laminate material can impact the machinability and dimensional stability of the PCB.

Design Complexity

The complexity of the slot design can also influence achievable tolerances:

-

Shape: Simple rectangular slots are easier to manufacture with tighter tolerances compared to complex shapes with curves or irregular geometries.

-

Size: Smaller slots may be more challenging to machine accurately, requiring tighter control over the manufacturing process.

-

Location: Slots located near the edges of the PCB or in close proximity to other features may be more difficult to maintain within tolerance.

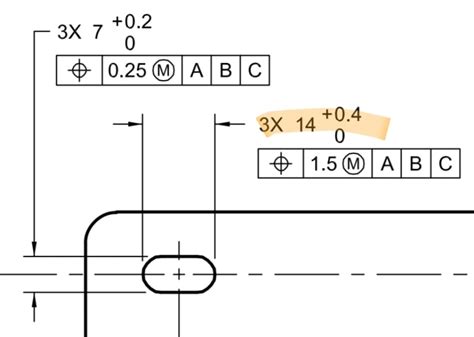

PCB Slot Tolerance Standards

Several industry standards provide guidance on PCB slot tolerances:

-

IPC-6012: This standard specifies the qualification and performance requirements for rigid printed boards, including slot tolerances.

-

IPC-2221: This standard provides guidelines for the design of printed boards, including recommendations for slot dimensions and tolerances.

-

IPC-7351: This standard focuses on land pattern geometries for surface mount design, including slot dimensions for component mounting.

These standards offer a range of tolerance classes based on the intended application and manufacturing capabilities. Some common tolerance classes include:

| Class | Tolerance Range |

|---|---|

| 1 | ±0.05 mm |

| 2 | ±0.10 mm |

| 3 | ±0.20 mm |

Designers should work closely with their PCB manufacturer to determine the appropriate tolerance class for their specific project, taking into account factors such as cost, lead time, and performance requirements.

Best Practices for Designing PCB Slots

To ensure the best possible slot tolerances on your PCB, consider the following best practices:

Keep It Simple

Whenever possible, design slots with simple, straightforward geometries. Avoid unnecessary curves, angles, or intricate shapes that may be difficult to manufacture accurately.

Provide Adequate Clearance

When designing slots for component mounting or connector clearance, provide sufficient space to accommodate the maximum tolerance range. This will help prevent interference or fitment issues during assembly.

Consider Manufacturing Capabilities

Work with your PCB manufacturer to understand their specific capabilities and limitations regarding slot tolerances. They can provide guidance on design optimization and help you select the most appropriate manufacturing process for your needs.

Use Appropriate Tooling

Ensure that your PCB manufacturer uses the appropriate tooling and processes to achieve the desired slot tolerances. High-quality, well-maintained equipment can significantly improve the accuracy and consistency of the final product.

Perform Thorough Testing

Before finalizing your PCB design, perform thorough testing to validate the slot dimensions and tolerances. This may involve creating prototype boards or using computer-aided design (CAD) software to simulate the manufacturing process and identify potential issues.

FAQ

- What is the typical tolerance range for PCB slots?

-

The typical tolerance range for PCB slots varies depending on the specific application and manufacturing process. Common tolerance classes range from ±0.05 mm to ±0.20 mm, with tighter tolerances generally requiring more advanced manufacturing techniques and higher costs.

-

How do I choose the appropriate slot tolerance for my PCB?

-

To choose the appropriate slot tolerance, consider factors such as the intended application, component requirements, manufacturing capabilities, and budget. Consult with your PCB manufacturer to determine the best tolerance class for your specific project.

-

Can I achieve tighter slot tolerances by using a different manufacturing process?

-

Yes, certain manufacturing processes, such as laser cutting or high-precision routing, can achieve tighter slot tolerances compared to traditional punching methods. However, these processes may also come with increased costs and longer lead times.

-

What happens if my PCB slots are out of tolerance?

-

If PCB slots are out of tolerance, it can lead to various issues, such as component misalignment, poor fit, or mechanical stress on the board. In some cases, out-of-tolerance slots may require rework or even complete redesign of the PCB.

-

How can I ensure my PCB slots meet the specified tolerances?

- To ensure your PCB slots meet the specified tolerances, follow best practices for design, such as keeping geometries simple, providing adequate clearance, and working closely with your manufacturer. Thorough testing and validation during the prototyping phase can also help identify and address any tolerance issues before full-scale production.

Conclusion

Understanding and controlling PCB slot tolerances is essential for ensuring the proper fit, function, and reliability of your printed circuit board. By considering factors such as manufacturing processes, material properties, and design complexity, you can work with your PCB manufacturer to achieve the desired slot tolerances for your specific application.

Following industry standards and best practices for PCB slot design can help optimize your board layout and minimize the risk of tolerance-related issues. Thorough testing and validation during the prototyping phase can further ensure that your PCB slots meet the specified requirements.

By taking a proactive approach to managing PCB slot tolerances, you can improve the overall quality and performance of your electronic devices while reducing the likelihood of costly rework or redesigns.

Leave a Reply