In printed circuit board (PCB) procurement context, the term “turnkey” refers to an end-to-end comprehensive partnership spanning design, fabrication, component procurement, assembly, testing and delivery from a single vendor allowing the customer to receive full built and tested boards ready for integration or end application usage in a plug-and-play manner.

This guide covers:

- Overview of Turnkey PCB Services

- Stages Involved in Turnkey Process

- Pros and Cons of Turnkey Approach

- Service Provider Selection Criteria

- Pricing Considerations

- Intellectual Property Concerns

- Applications Suitability

- Alternative Approaches Comparison

- FAQs

Let’s get started understanding ins and outs of outsourcing electronics manufacturing under turnkey model to simplify and accelerate product development.

Overview of Turnkey PCB Services

Traditionally, procuring printed circuit boards for electronics projects involved coordination across multiple disparate specialized entities – design houses created board layouts, board shops fabricated bare PCBs, component distributors stocked parts for procurement, contract manufacturers assembled boards, testing labs validated builds etc.

Turnkey model consolidates this fragmented supply chain – a single partner provides umbrella oversight across the entire gamut of electronics manufacturing stages culminating in delivery of vetted functional boards matching quality, budget and lead time needs.

Stages Encompassed in Turnkey PCB Services

A fully integrated turnkey PCB partner provides following manufacturing activities:

1. Design Services

- Schema reviews

- PCB layouts optimizing design for manufacturing

- Simulation and signal integrity analysis

- Component selection recommendations

- Design for testing guidance

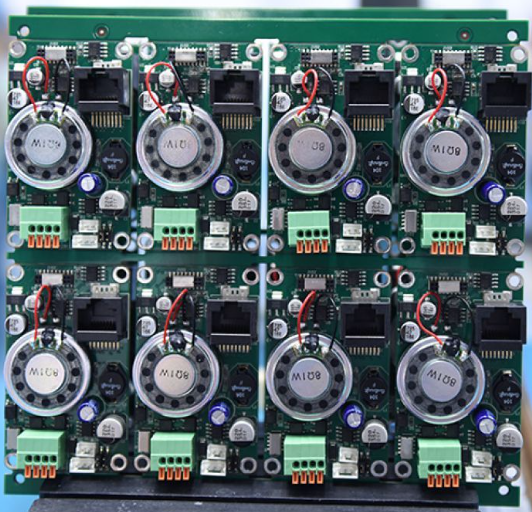

2. Fabrication and Assembly

- Board fabrication inclusive of sourcing suitable materials

- Procurement of components specified in bill of materials

- Programming automated SMT pick-and-place machines

- Solder paste printing and solder reflow

- Conformal coating for ruggedization

3. Testing

- Flying probe testing

- ICT fixture validation

- Burn-in stress testing

- Feature validation testing

**4. Supply Chain Management **

- Demand planning

- Inventory management

- Shipping and logistics

5. Data Management

- Revision control

- Configuration audits

- Progress status monitoring

- Yield analytics

Using turnkey partner right from conceptual design phase allows tapping into their manufacturing expertise towards design for excellence (DFX) practices ensuring reliable production outcomes.

Now let’s weigh some key advantages and tradeoffs.

Pros and Cons of Turnkey PCB Approach

Benefits

Faster time-to-market – Parallel execution of activities avoids serial delays allowing tight development schedules.

Single point accountability – Without finger pointing between fragmented vendors, customers have consistent touchpoint throughout product lifecycle.

Cost efficiencies – Bulk component purchases, optimized inventories and established test facilities lower per unit costs.

Quality consistency – Process maturity, infrastructure stability and employee continuity maintain uniform quality levels.

Improved manufacturability – Early DFM analysis and testability design guidance ensure smooth manufacturing ramp up.

Reduced risks – Turnkey owners apply program management rigor and change control minimizing unexpected headaches.

Drawbacks

Customization challenges – High mix volatility across customer projects strains operational flexibility of turnkey lines tuned for volume consistency.

Proprietary design loss – Loss of IPR control requiring extensive legal contracts protecting intellectual property shared for ease of outsourced manufacturing.

Geographic barriers – Communication overhead and logistical delays working with offshore turnkey handlers during product development cycles.

Vendor lock-in – High switching costs disincentivizes changing partners inducing complacency among incumbents.

For quick product builds, turnkey model offers the shortest path from concept to shipping for enterprises lacking expertise across electronics hardware domains allowing them to stay laser focused on their core competence like software or applications.

Criteria for Selecting Turnkey PCB Partner

Picking the right turnkey electronics manufacturing collaborator determines success of the partnership in reliably delivering quality products. Key selection dimensions include:

Technical capabilities – Advanced assembly skills like ultra-fine pitch BGAs, 01005 passives, high density PCBs etc. reveal sophistication.

Certifications – Compliance with IPC standards and ISO processes indicate reproducible results.

Equipment and facilities – Utilizing latest fully automated tools for fabrication, component placement inspection etc. ensures precision output.

Miniaturization skills – Excellence in dense electronics packaging highlights competencies given global trends towards smart miniaturized products across verticals.

Quality processes – Statistical control tracking and continuous improvement practices boost consistency.

Proactive communication – Interactions beyond just order taking towards design recommendations and progress updates.

Business continuity planning – Redundancies across supply chain, IT systems andEmployee retention policies ensure consistent deliveries across years.

Domain expertise – Exposure across related technologies like sensors, antennas, power systems indicates expanded capabilities.

Data protection infrastructure – Actions like compartmentalized access controls, cyber insurance coverage, infrastructure audits assuage IP confidentiality apprehensions.

Cultural compatibility – Convergent work ethics and transparency expectations allows smoother collaboration.

Take your time initially qualifying various turnkey contractors checking with references before sealing long term strategic outsourcing partnerships.

Pricing Considerations for Turnkey Services

Determining true net costs across chosen turnkey partner requires tallying both direct and indirect expenses accrued across various manufacturing activities spanning extended multi-year contract periods:

NRE charges – Upfront non-recurring engineering fees are common for developing initial board designs, simulation builds, testing fixtures etc. These gets amortized over subsequent recurring orders.

Component costs – BOM Prices fluctuates across years depending on market supply-demand dynamics especially for specialty parts involving long re-order lead times. Budget additional procurement buffer for hard to source items.

Inventory carrying charges – Turnkey vendors stock substantial components taking balance sheet hits requiring additional working capital costs to be recovered from customers.

Yield fallouts – Ensuring adequate fallout margins along anticipated scrap rates shields against unexpected build failures especially for newer complex assemblies.

Gold and NCNR parts – Expediting fees for long lead items also accrues added logistics rush handling expenses.

Value engineering – Be wary of turnkey contractors cheaping out swappingcomponents without consulting design teams risking field failure rates.

Software and tooling infrastructure – Technology platform licensing, equipment depreciation and maintenance charges borne by turnkey partner gets billed back.

Quality and testing coverage – Ensure pricing accommodates adequate inspection sampling rates and test coverage criteria satisfying reliability goals.

RMA and warranty – Negotiate detailed return material authorization and repair policies upfront capping customer risks allowing for deviations from idealized quality targets.

IP protection services – Data security audits, access control systems and legal safeguards against IP theft require investments eventually billed to customers.

Thus exhaustive due diligence across above hidden aspects is mandatory before signing “too good be true” turnkey contracts purely assessing upfront quoted prices.

Intellectual Property Protection with Turnkey

Outsourcing manufacturing basics like PCB fabrication and component assembly to turnkey entities seems innocuous initially. However, the extensive product design details sharing required allows contract manufacturers accumulating tremendous amounts of sensitive IP often advanced of what patent filings may have covered.

Hence customers need being proactive to safeguard IPR with prudent turnkey partnerships leveraging:

- Strict NDAs – Non-disclosure agreements must mandate absolute confidentiality against product data leakage including stiff financial penalties for violations. Mandate disclosures around other customer conflicts.

- Restrict file access – Limit read-write permissions and physically secure data transfers using hardened encrypted drives. Compartmentalize file access only on need to know basis.

- Obfuscate design data – Mask sensitive identifiers with placeholders. Manipulate dimensions on drawings to conceal actual sizes. Share sub-system level diagrams avoiding holistic view.

- Background checks – Audit key employees working on contracts against past criminal records or litigation validating trustworthiness.

- Secure manufacturing – Install verified video surveillance covering assembly lines alongside logging systems tracking data access preventing potential IP thefts.

- **Legal safeguards ** – Register patents early around technologies even while engaging turnkey partners allowing pursuing infringements remedies later if intellectual theft suspected.

But beyond contractual measures, partner only with highly reputed turnkey operators sharing aligned goals eliminating temptation to simply abscond with innovative products through betrayal of trust.

Applications Suitable for Turnkey Model

Here are prime product categories benefiting under turnkey outsourced arrangement for accelerating manufacturing:

Mid-volume consumer electronics – Where project volumes donot justify large internal corporate investments into specialized manufacturing infrastructure but require wider supply chain coordination ill-suited for small hobbyist prototyping shops to scale up reliably. Example – Wearables, home IoT products, educational electronics, DIY kits etc.

Regulated medical devices – Where compliance requirements like FDA approval require operating under established quality management protocols provided by turnkey entities allowing medical startups staying focused on end applications be it patient monitors, analyzer equipment or assistive technology products. Most turnkey operators already have industry credentials easing certification.

Short lifespan releases – Industries characterized by short innovation cycles or frequent model refreshes like mobile phones make vertical integration into internal production facilities inefficient. Outsourced assembly allows faster reconfiguration between product SKUs reacting to market demands.

University startup prototypes – Academic researchers often lack realistic assessment around commercialization complexities involved in launching science and lab based prototypes as finished products. Turnkey route helps reality check viability while progressing testing and refinement toward product maturity.

Alternative Approaches Compared to Turnkey Services

Here are popular alternative options contrasted against turnkey model for fulfilling electronics manufacturing requirements:

| Manufacturing Model | Pros | Cons |

|---|---|---|

| Full Internal Capability | Protects IP <br> Tightest control <br> Customization responsive | High infrastructure costs <br> Steep learning curves |

| **Individual Vendor Sourcing ** | Choose best capabilities across segments <br> Maintain supplier competition | Lack of end-to-end ownership <br> Overlapping coordination overheads eroding savings |

| Hybrid Integrator | Leverages external capacity <br> Retains core control on proprietary subsystems | Long term model drift towards hollowing out towards fully outsourced |

| Turnkey Outsourcing | Faster speed by leveraging partner competencies <br> Pay as you go flexible capacity | Risks quality erosion over time <br> Contractual dependency lock-ins |

Balancing across metrics around speed, quality, costs and control dictate what combination of insourced vs outsourced electronics manufacturing capabilities best optimizes overall product goals.

Frequently Asked Questions

Here are some common turnkey PCB queries:

Q. Can a startup control quality with turnkey?

Startups can steer initial quality baseline by extensive design reviews, process audits and sampling based inspections before large volume commitments.

Q. Does turnkey allow customizing assembled boards?

Component selection flexibility varies across vendors. Discuss your priority parts needs upfront if requiring finer control over bills of materials.

Q. Can turnkey services scale across risk production?

Analyze capacity scalability for supporting graduated volumes right from prototypes to high volume manufacturing based on market response and unique flexibility requirements.

Q. What compliance assistance does turnkey offer?

Turnkey operators stock range of certified materials like Rohs components. Some assist documentation needed for emission, regulatory approvals. Know availability upfront.

Q. How to lower turnkey dependency risks?

Maintain multiple turnkey partners for same product so no single vendor becomes indispensable. Strategically make or buy – periodically transfer critical processes internally.

In summary, turnkey PCB outsourcing aims squarely at accelerating time-to-market leveraging aggregate ecosystem competencies allowing enterprises focus on their core differentiators be it proprietary technology or embedded software or disruptive business model providing the competitive edge. But sufficient transparency, upgrades commitments must bind contracts ensuring quality keeps pace as production volumes scale up within vibrant technology partnerships.

Leave a Reply