PCB Assembly Blog

-

How do you qualify a PCB contract manufacturer?

Posted by

–

Read more: How do you qualify a PCB contract manufacturer?

Read more: How do you qualify a PCB contract manufacturer?Why Choose a PCB Contract Manufacturer? Before diving into the qualification process, let’s briefly discuss the benefits of working with a PCB contract manufacturer: Cost savings: Outsourcing PCB manufacturing to a contract manufacturer can significantly reduce your production costs, as they have the necessary equipment, expertise, and economies of scale. […]

-

What does EMS stand for in electronics?

Posted by

–

Read more: What does EMS stand for in electronics?

Read more: What does EMS stand for in electronics?Understanding EMS and its role in the electronics industry The electronics industry is a complex and fast-paced sector that requires a high level of expertise, advanced technology, and efficient processes to meet the ever-growing demand for electronic products. EMS providers play a crucial role in this industry by offering a […]

-

What is an IMS PCB?

Posted by

–

Read more: What is an IMS PCB?

Read more: What is an IMS PCB?Key Features of IMS PCBs Thermal Management The primary advantage of an IMS PCB is its excellent thermal management capabilities. The metal substrate, typically aluminum or copper, acts as a heat sink, efficiently transferring heat away from the components mounted on the board. This helps to maintain a stable operating […]

-

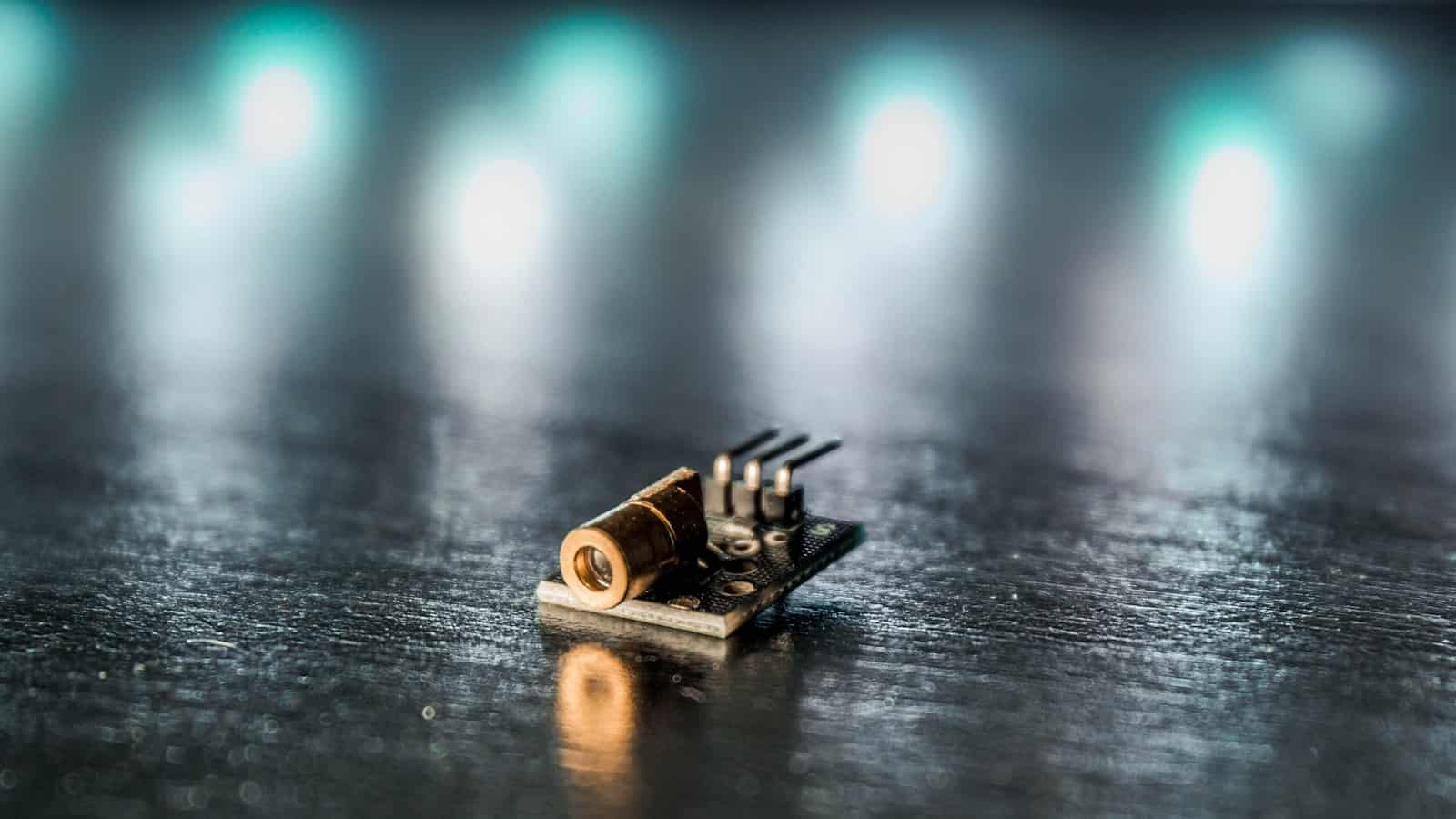

Can I laser cut PCB?

Posted by

–

Read more: Can I laser cut PCB?

Read more: Can I laser cut PCB?What is Laser Cutting? Laser cutting is a precise and versatile manufacturing process that uses a high-powered laser beam to cut, engrave, or mark various materials. The laser beam is focused onto the material surface, and the intense heat generated by the laser vaporizes or melts the material along the […]

-

What is OSP in PCB?

Posted by

–

Read more: What is OSP in PCB?

Read more: What is OSP in PCB?Introduction to OSP in PCB OSP, or Organic Solderability Preservative, is a surface finish that is commonly used in the manufacturing of printed circuit boards (PCBs). It is a cost-effective and environmentally friendly alternative to other surface finishes such as Hot Air Solder Leveling (HASL), Electroless Nickel Immersion Gold (ENIG), […]

-

How to Design PCB Antennas

Posted by

–

Read more: How to Design PCB Antennas

Read more: How to Design PCB AntennasIntroduction to PCB Antennas Printed circuit board (PCB) antennas are becoming increasingly popular for wireless devices due to their low cost, small size, and ease of integration. PCB antennas are simply conductive traces printed directly onto a circuit board, eliminating the need for a separate antenna component. This allows PCB […]

-

What are the steps of PCB assembly?

Posted by

–

Read more: What are the steps of PCB assembly?

Read more: What are the steps of PCB assembly?The PCB Assembly Process The PCB assembly process typically involves the following steps: Design and Fabrication Solder Paste Application Component Placement Reflow Soldering Inspection and Testing Conformal Coating Final Assembly and Packaging Let’s dive into each of these steps in more detail. 1. Design and Fabrication The first step in […]

-

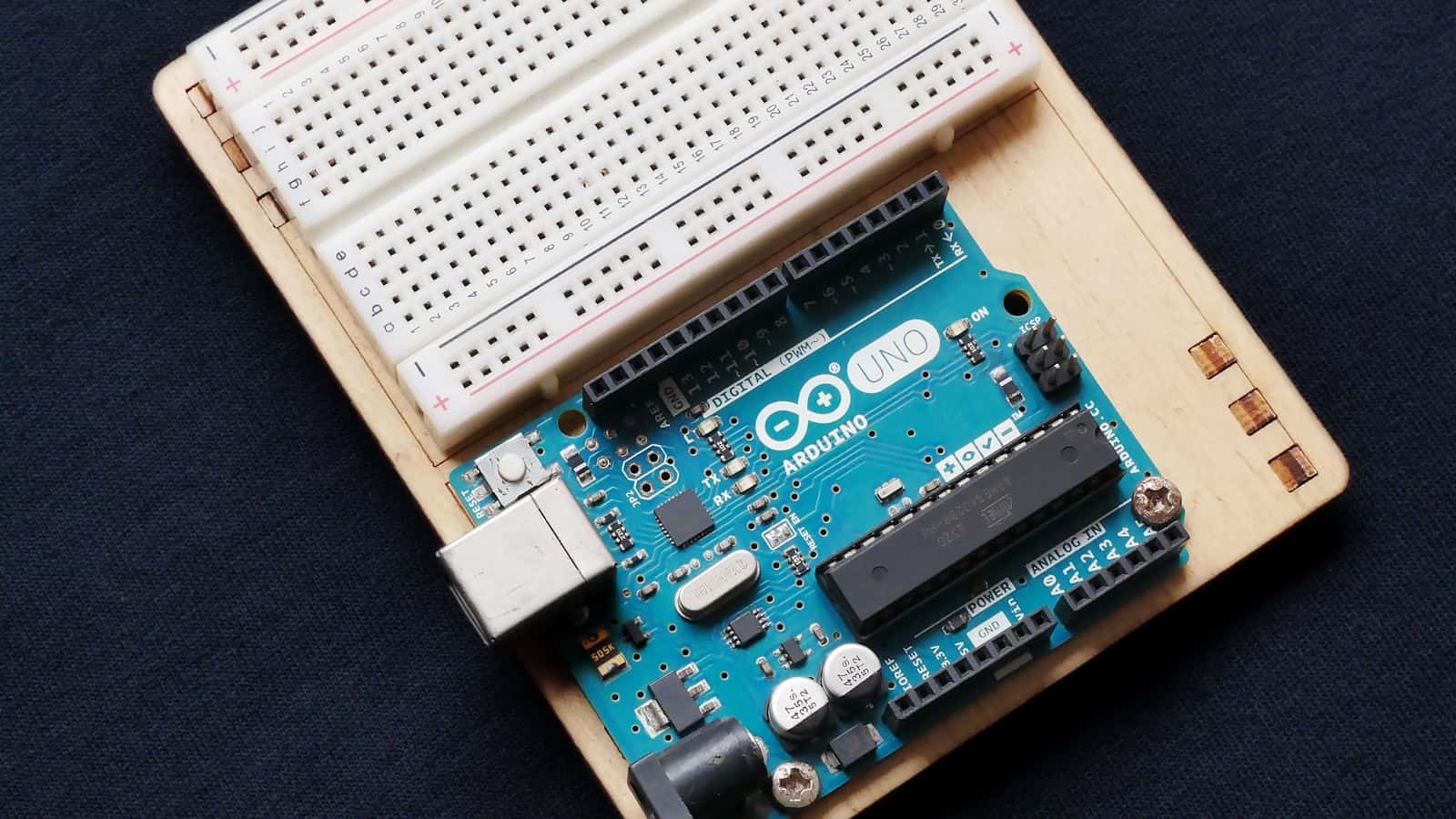

How do you draw a PCB circuit?

Posted by

–

Read more: How do you draw a PCB circuit?

Read more: How do you draw a PCB circuit?What is a PCB? A PCB is a flat board made of insulating material, such as fiberglass or plastic, with conductive tracks, pads, and other features etched from copper sheets laminated onto the board. It is used to mechanically support and electrically connect electronic components using conductive pathways, tracks, or […]

-

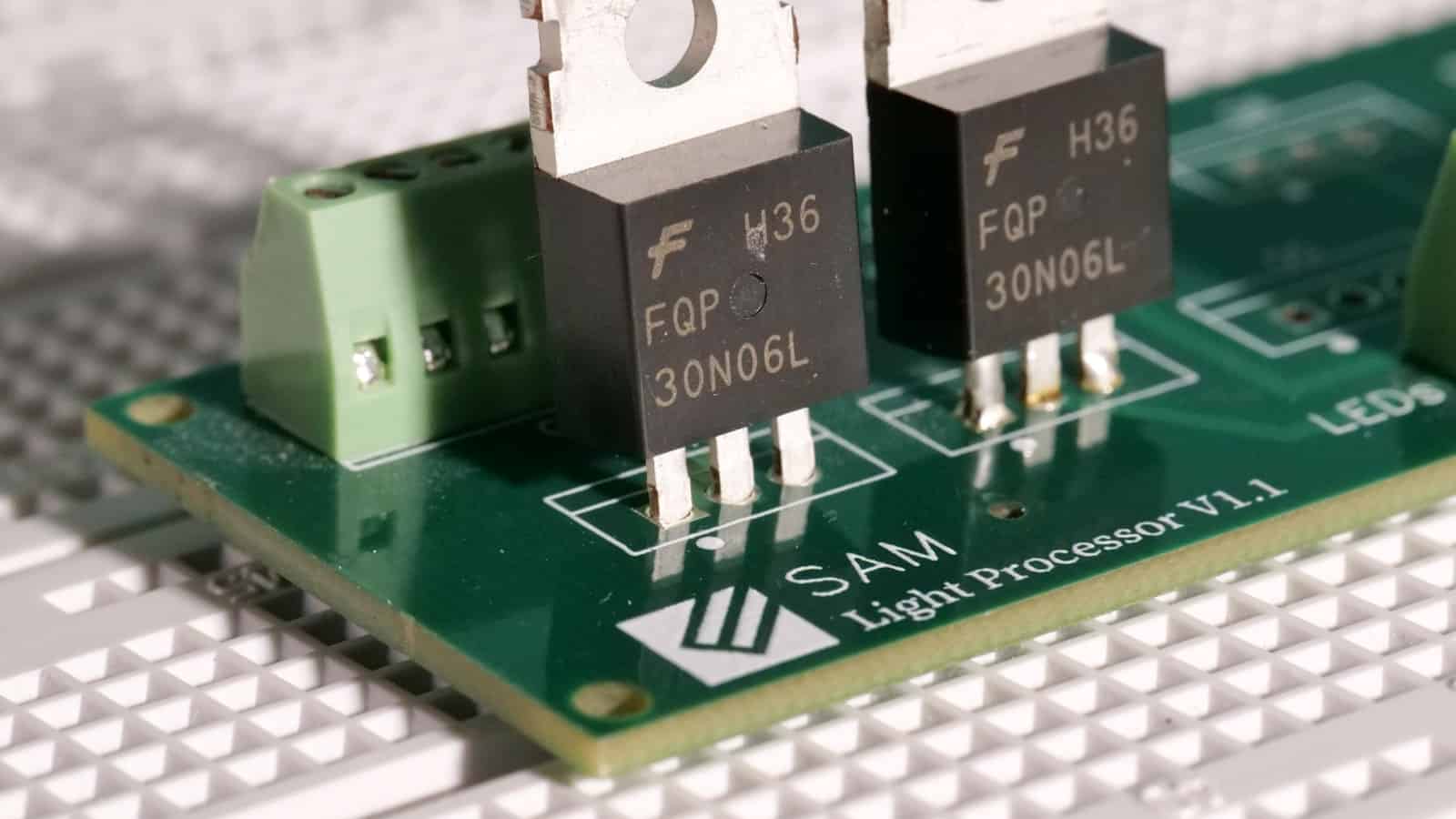

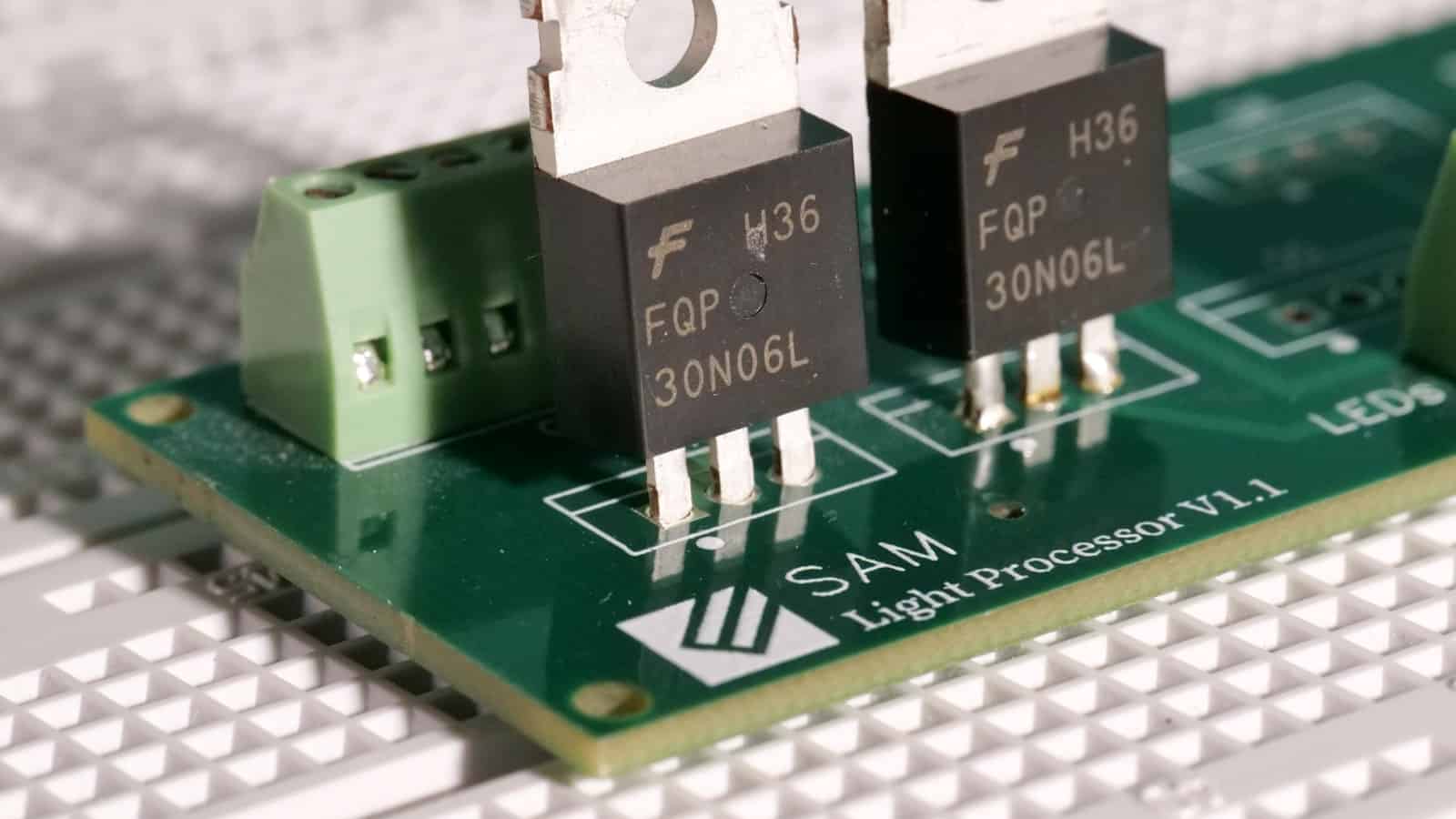

What is heatsink in PCB?

Posted by

–

Read more: What is heatsink in PCB?

Read more: What is heatsink in PCB?Understanding the Basics of Heatsinks What is a Heatsink? A heatsink is a passive heat exchanger that is designed to absorb and dissipate heat generated by electronic components, such as processors, power transistors, and voltage regulators. The primary purpose of a heatsink is to maintain the temperature of these components […]

-

What is PCB factory?

Posted by

–

Read more: What is PCB factory?

Read more: What is PCB factory?The Role of a PCB Factory The primary function of a PCB factory is to manufacture high-quality PCBs according to the specifications provided by their clients. This process involves several steps, including: Design and Engineering Material Selection Fabrication Assembly Testing and Quality Control Design and Engineering Before the manufacturing process […]