PCB Assembly Blog

-

What is the minimum component clearance for IPC?

Posted by

–

Read more: What is the minimum component clearance for IPC?

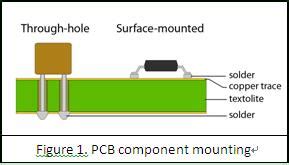

Read more: What is the minimum component clearance for IPC?Understanding PCB component clearance PCB component clearance refers to the minimum distance required between components, traces, and other features on a PCB to ensure proper assembly, soldering, and operation. Adequate clearances help prevent short circuits, unwanted interactions, and manufacturing defects. Why is Component Clearance Important? Maintaining proper component clearances is […]

-

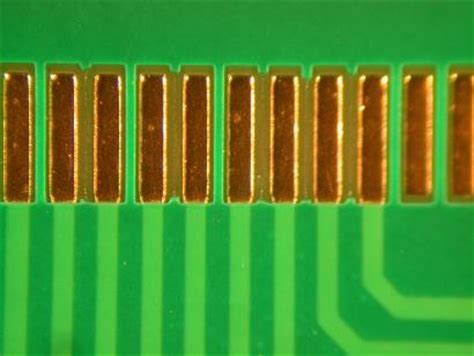

What is via in pad plating?

Posted by

–

Read more: What is via in pad plating?

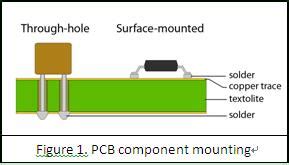

Read more: What is via in pad plating?How Via-in-pad plating Works In a conventional PCB design, vias are typically located outside the surface mount pads to avoid interfering with the soldering process. However, as electronic devices become more compact and complex, there is an increasing demand for higher-density PCB layouts. Via-in-pad plating addresses this challenge by placing […]

-

Bare Board Testing

Posted by

–

Read more: Bare Board Testing

Read more: Bare Board TestingWhat is Bare Board Testing? Bare board testing, also known as printed circuit board (PCB) testing, is a crucial step in the manufacturing process of electronic devices. It involves testing the PCB before any components are mounted on it to ensure that it functions as intended and meets the required […]

-

What paste to be used on heat sink?

Posted by

–

Read more: What paste to be used on heat sink?

Read more: What paste to be used on heat sink?Introduction to Heatsink Paste Heatsink paste, also known as thermal paste, thermal grease, thermal compound, or thermal interface material (TIM), is a thermally conductive substance used to fill the gaps between a heat sink and the heat-generating component it is designed to cool, such as a CPU, GPU, or power […]

-

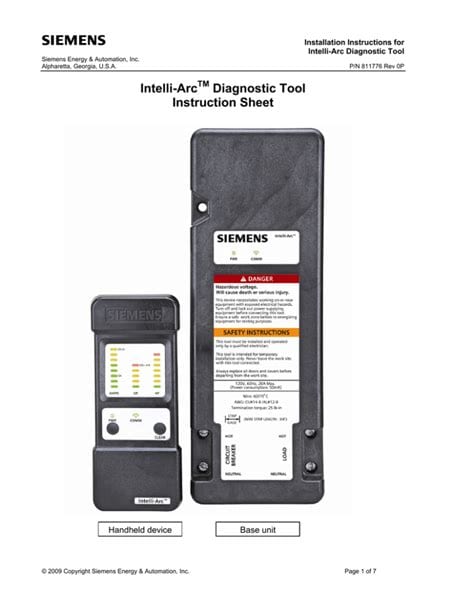

Elsyca Intellitool Matrix plating project

Posted by

–

Read more: Elsyca Intellitool Matrix plating project

Read more: Elsyca Intellitool Matrix plating projectIntroduction to Intellitool Matrix Plating Technology Elsyca, a leading provider of advanced plating solutions, has recently launched its groundbreaking Intellitool Matrix plating system. This innovative technology revolutionizes the electroplating industry by offering unprecedented control, efficiency, and flexibility in the plating process. The Intellitool Matrix system is designed to address the […]

-

Where to place the PCB in the oven?

Posted by

–

Read more: Where to place the PCB in the oven?

Read more: Where to place the PCB in the oven?Introduction to PCB Oven Placement Proper placement of printed circuit boards (PCBs) in a reflow oven is critical for achieving high-quality solder joints and reliable electronic assemblies. The location of the PCB within the oven chamber directly impacts the uniformity of heat distribution, which in turn affects the reflow soldering […]

-

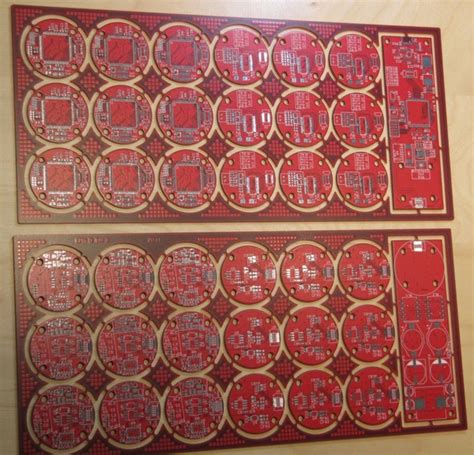

How to Panelise Small PCBs

Posted by

–

Read more: How to Panelise Small PCBs

Read more: How to Panelise Small PCBsWhat is Panelising PCBs? Panelising PCBs refers to the process of combining multiple individual printed circuit boards (PCBs) into a single larger panel. This is done to allow for more efficient and cost-effective manufacturing, as it enables the production of multiple PCBs in a single fabrication run. When you have […]

-

What is Soldermask (SM)?

Posted by

–

Read more: What is Soldermask (SM)?

Read more: What is Soldermask (SM)?Table of Contents Introduction to Soldermask (SM) The Purpose and Importance of Soldermask Types of Soldermask Liquid Photoimageable Soldermask (LPISM) Dry Film Soldermask Properties and Characteristics of Soldermask Adhesion Thermal Resistance Chemical Resistance Electrical Insulation Color Options The Soldermask Application Process Surface Preparation Soldermask Coating Imaging and Developing Curing Quality […]

-

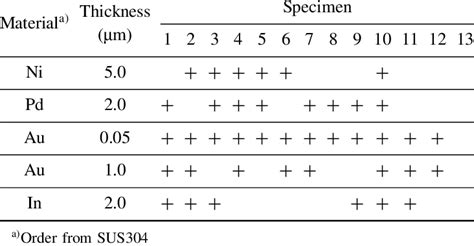

What is Plating Index Solutions

Posted by

–

Read more: What is Plating Index Solutions

Read more: What is Plating Index SolutionsIntroduction to Plating Index Plating index is a critical parameter in the electroplating industry that measures the efficiency and quality of the plating process. It is a numerical value that indicates the amount of metal deposited on the substrate surface during the electroplating process. The plating index is influenced by […]

-

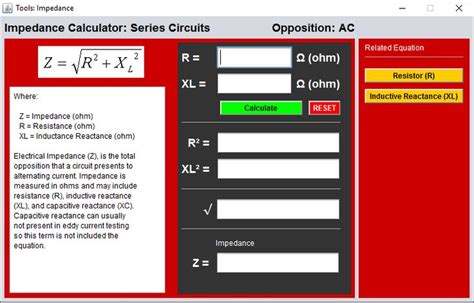

Defined Impedance Calculators

Posted by

–

Read more: Defined Impedance Calculators

Read more: Defined Impedance CalculatorsWhat are Impedance Calculators? Impedance calculators are essential tools for engineers, designers, and technicians working with electrical circuits and systems. These calculators allow users to determine the total opposition to current flow in an alternating current (AC) circuit, which is known as impedance. Impedance is a complex quantity that combines […]