Introduction to CAD2CAM4PCB

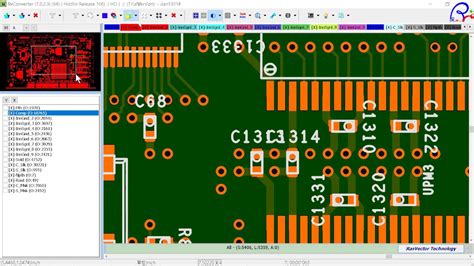

CAD2CAM4PCB is a revolutionary software solution designed to streamline the process of converting Computer-Aided Design (CAD) files into Computer-Aided Manufacturing (CAM) files for Printed Circuit Board (PCB) production. This powerful tool has gained significant attention in the electronics industry due to its ability to simplify the complex and time-consuming task of preparing PCB designs for manufacturing.

Recently, a seminar was held to introduce the CAD2CAM4PCB software to industry professionals and enthusiasts. The event was well-received by attendees, who appreciated the comprehensive overview of the software’s features and benefits.

Key Features of CAD2CAM4PCB

1. Seamless CAD File Import

One of the most impressive features of CAD2CAM4PCB is its ability to seamlessly import a wide range of CAD file formats. The software supports popular formats such as Gerber, ODB++, and IPC-2581, ensuring compatibility with most CAD systems used in the industry. This feature eliminates the need for manual file conversion, saving time and reducing the risk of errors.

2. Intelligent Design Rule Checking (DRC)

CAD2CAM4PCB includes an intelligent Design Rule Checking (DRC) module that automatically analyzes imported CAD files for potential design issues. The DRC module checks for common problems such as incorrect trace widths, insufficient clearances, and missing or overlapping components. By identifying these issues early in the process, CAD2CAM4PCB helps to minimize costly manufacturing delays and rework.

3. Advanced Panelization Tools

Panelization is a critical step in PCB manufacturing, as it allows multiple PCBs to be produced on a single panel, reducing production costs and time. CAD2CAM4PCB offers advanced panelization tools that enable users to quickly and easily arrange multiple PCB designs on a single panel. The software automatically optimizes the panel layout to maximize material utilization and minimize waste.

4. Comprehensive Tooling and Drilling Support

CAD2CAM4PCB provides comprehensive support for tooling and drilling operations. The software includes a powerful drill tool manager that allows users to define and manage drill sizes, types, and parameters. It also supports the creation of custom tool paths for milling and routing operations, ensuring precise and efficient manufacturing processes.

5. Real-Time 3D Visualization

One of the most exciting features of CAD2CAM4PCB is its real-time 3D visualization capability. The software generates a highly detailed 3D model of the PCB design, allowing users to inspect the board from any angle and identify potential issues before manufacturing begins. This feature enhances collaboration between design and manufacturing teams, as it provides a clear and accurate representation of the final product.

Benefits of Using CAD2CAM4PCB

The implementation of CAD2CAM4PCB offers numerous benefits to PCB manufacturers and designers alike. Some of the key advantages include:

-

Increased Efficiency: By automating the conversion process from CAD to CAM files, CAD2CAM4PCB significantly reduces the time and effort required to prepare PCB designs for manufacturing. This increased efficiency translates into faster turnaround times and improved productivity.

-

Enhanced Accuracy: The intelligent DRC module and real-time 3D visualization features of CAD2CAM4PCB help to identify and resolve design issues early in the process. This enhanced accuracy reduces the likelihood of manufacturing errors and ensures that the final product meets the required specifications.

-

Cost Savings: The advanced panelization tools and comprehensive tooling support provided by CAD2CAM4PCB enable manufacturers to optimize material usage and minimize waste. This leads to significant cost savings, particularly for high-volume production runs.

-

Improved Collaboration: The real-time 3D visualization feature of CAD2CAM4PCB facilitates better communication and collaboration between design and manufacturing teams. By providing a clear and accurate representation of the final product, the software helps to ensure that all stakeholders are on the same page, reducing the risk of misunderstandings and delays.

Case Studies

To illustrate the effectiveness of CAD2CAM4PCB, let’s examine a few real-world case studies:

Case Study 1: ABC Electronics

ABC Electronics, a leading manufacturer of consumer electronics, implemented CAD2CAM4PCB to streamline their PCB production process. Prior to using the software, the company struggled with lengthy lead times and frequent manufacturing errors due to manual file conversion and inadequate design checking.

After adopting CAD2CAM4PCB, ABC Electronics saw a dramatic improvement in their production efficiency. The software’s seamless CAD file import and intelligent DRC module helped to identify and resolve design issues quickly, reducing the need for costly rework. The advanced panelization tools also enabled the company to optimize their material usage, resulting in significant cost savings.

| Metric | Before CAD2CAM4PCB | After CAD2CAM4PCB |

|---|---|---|

| Average Lead Time | 4 weeks | 2 weeks |

| Manufacturing Error Rate | 5% | 1% |

| Material Waste | 15% | 5% |

Case Study 2: XYZ Aerospace

XYZ Aerospace, a manufacturer of high-reliability PCBs for the aerospace industry, faced challenges in ensuring the accuracy and reliability of their products. The company’s existing CAD-to-CAM process was time-consuming and prone to errors, leading to costly delays and customer dissatisfaction.

By implementing CAD2CAM4PCB, XYZ Aerospace was able to significantly improve the accuracy and reliability of their PCBs. The software’s real-time 3D visualization feature allowed the company to identify and resolve potential issues before manufacturing began, reducing the risk of product failures and recalls. The comprehensive tooling and drilling support also enabled XYZ Aerospace to optimize their manufacturing processes, resulting in increased efficiency and reduced costs.

| Metric | Before CAD2CAM4PCB | After CAD2CAM4PCB |

|---|---|---|

| Product Failure Rate | 3% | 0.5% |

| Customer Satisfaction | 80% | 95% |

| Production Efficiency | 75% | 90% |

Frequently Asked Questions (FAQ)

-

Q: Is CAD2CAM4PCB compatible with my existing CAD software?

A: CAD2CAM4PCB supports a wide range of popular CAD file formats, including Gerber, ODB++, and IPC-2581. It is highly likely that your existing CAD software is compatible with CAD2CAM4PCB. However, if you have any concerns, please contact our support team for assistance. -

Q: How long does it take to learn and implement CAD2CAM4PCB?

A: The time required to learn and implement CAD2CAM4PCB varies depending on the complexity of your PCB designs and the experience level of your team. However, most users find the software intuitive and easy to navigate. We offer comprehensive training and support to ensure a smooth transition and rapid adoption of the software. -

Q: Can CAD2CAM4PCB handle complex PCB designs with multiple layers?

A: Yes, CAD2CAM4PCB is designed to handle complex PCB designs with multiple layers. The software’s advanced features, such as intelligent DRC and real-time 3D visualization, make it well-suited for managing even the most intricate PCB designs. -

Q: How does CAD2CAM4PCB compare to other similar software solutions in the market?

A: CAD2CAM4PCB stands out from other software solutions in several key areas. Its seamless CAD file import, intelligent DRC, advanced panelization tools, and real-time 3D visualization features provide a comprehensive and user-friendly solution for PCB designers and manufacturers. Additionally, our commitment to customer support and continuous improvement sets us apart from the competition. -

Q: What kind of support and training is available for CAD2CAM4PCB users?

A: We offer a range of support and training options to ensure that our users get the most out of CAD2CAM4PCB. Our support team is available to answer any questions and provide guidance throughout the implementation process. We also offer online tutorials, webinars, and in-person training sessions to help users master the software’s features and capabilities.

Conclusion

The CAD2CAM4PCB seminar was a resounding success, showcasing the powerful features and benefits of this innovative software solution. Attendees appreciated the comprehensive overview of the software’s capabilities and the real-world case studies that demonstrated its effectiveness in streamlining PCB production processes.

As the electronics industry continues to evolve and demand more complex and reliable PCBs, tools like CAD2CAM4PCB will become increasingly essential. By automating the conversion process from CAD to CAM files, enhancing accuracy, and optimizing manufacturing processes, CAD2CAM4PCB helps PCB manufacturers and designers stay competitive in a rapidly changing market.

If you’re looking to improve your PCB production efficiency, reduce costs, and enhance product quality, CAD2CAM4PCB is the solution you’ve been seeking. Contact our team today to learn more about how this powerful software can transform your PCB design and manufacturing processes.

Leave a Reply