PCB Data Files

Gerber Files

Gerber files are the most common and widely accepted format for PCB data exchange. They contain information about the copper layers, solder mask, silkscreen, and drill holes of your PCB. Gerber files are generated from your PCB design software and are used by the manufacturer to create the physical boards.

Typical Gerber files include:

| File Extension | Description |

|---|---|

| .GTL | Top Layer Copper |

| .GBL | Bottom Layer Copper |

| .GTO | Top Overlay (Silkscreen) |

| .GBO | Bottom Overlay (Silkscreen) |

| .GTS | Top Solder Mask |

| .GBS | Bottom Solder Mask |

| .GKO | Keep-Out Layer |

| .GPT | Top Paste Mask |

| .GPB | Bottom Paste Mask |

When generating Gerber files, ensure that you use the correct settings, such as the file format (RS-274X), aperture list, and coordinate format (absolute or incremental).

Drill Files

Drill files contain information about the holes that need to be drilled in your PCB. These holes are used for through-hole components, vias, and mounting. There are two main types of drill files:

-

Excellon Drill File (.DRL): This file contains the coordinates and sizes of the drill holes. It is essential to specify the correct drill unit (metric or imperial) and the number of decimal places.

-

Drill Map File (.PDF or .DXF): This file provides a visual representation of the drill holes on your PCB. It helps the manufacturer to verify the hole sizes and locations.

Pick and Place File

The pick and place file (also known as the centroid file or X-Y file) contains information about the placement of surface mount components on your PCB. This file is used by the manufacturer’s automated assembly machines to accurately position and orient the components on the board.

A pick and place file typically includes:

- Reference designator for each component

- X and Y coordinates of the component centroid

- Rotation angle of the component

- Side of the board (top or bottom)

The file format for pick and place data can vary, but the most common formats are .CSV and .TXT.

Bill of Materials (BOM)

The bill of materials (BOM) is a comprehensive list of all the components required to assemble your PCB. It helps the manufacturer to procure the correct components and ensure that your PCB is assembled according to your specifications.

A BOM should include the following information for each component:

- Reference designator

- Manufacturer part number

- Description

- Quantity

- Footprint

- Value (if applicable)

It is essential to provide an accurate and up-to-date BOM to avoid any discrepancies during the assembly process.

PCB Stackup

The PCB stackup file provides information about the structure and materials of your PCB. It specifies the number of layers, their order, and the materials used for each layer. This information is crucial for the manufacturer to ensure that your PCB meets your design requirements and functions as intended.

A typical PCB stackup file includes:

- Number of layers

- Thickness of each layer

- Material type for each layer (e.g., FR-4, Rogers, etc.)

- Copper weight for each layer

- Finished thickness of the PCB

- Impedance requirements (if applicable)

Assembly Drawing

An assembly drawing is a visual representation of your PCB that provides information about the component placement, orientation, and any special assembly instructions. It helps the manufacturer to understand your PCB assembly requirements and ensures that the final product meets your expectations.

An assembly drawing should include:

- Board dimensions

- Component locations and orientations

- Silkscreen legends and markings

- Any special assembly instructions or notes

Preparing Your PCB Data Files

Before uploading your PCB data files to the manufacturer, it is essential to ensure that they are complete, accurate, and properly formatted. Here are some steps you can take to prepare your files:

-

Review your design: Double-check your PCB design for any errors, inconsistencies, or design rule violations. Ensure that all the components are correctly placed and oriented and that the routing is optimal.

-

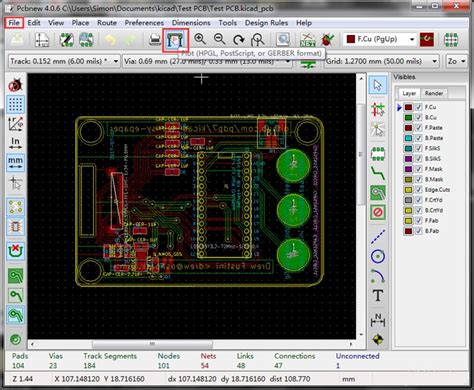

Generate output files: Use your PCB design software to generate the necessary output files, such as Gerber files, drill files, and pick and place files. Ensure that you use the correct settings and file formats.

-

Verify the files: Use a Gerber viewer or CAM software to verify that your output files are complete and accurate. Check for any missing layers, incorrect apertures, or formatting issues.

-

Package the files: Compress all your PCB data files into a single archive file (e.g., .ZIP or .RAR) to make it easier for the manufacturer to download and manage your data.

-

Provide clear instructions: Include a README file or a cover letter that provides clear instructions to the manufacturer about your PCB order. Specify any special requirements, such as surface finish, material type, or testing procedures.

Frequently Asked Questions (FAQ)

-

What happens if I provide incomplete or incorrect PCB data files?

If you provide incomplete or incorrect PCB data files, it can lead to delays in your order, additional costs, or even the production of faulty boards. The manufacturer may need to contact you for clarification or request updated files, which can prolong the lead time. In some cases, the manufacturer may proceed with the production based on the provided files, resulting in boards that do not meet your requirements. -

Can I use different PCB design software to generate the data files?

Yes, you can use any PCB design software that can generate the required output files in the standard formats (e.g., Gerber, Excellon, etc.). However, ensure that you use the correct settings and file formats that are compatible with the manufacturer’s requirements. -

What if I don’t have a pick and place file?

If you don’t have a pick and place file, the manufacturer may need to manually place the components on your PCB, which can increase the assembly time and cost. In some cases, the manufacturer may be able to generate a pick and place file based on your PCB design files, but this may incur additional charges. -

How do I ensure that my PCB stackup meets my design requirements?

To ensure that your PCB stackup meets your design requirements, provide clear and detailed specifications in your stackup file. Include information about the number of layers, material type, copper weight, and any special requirements, such as impedance control or controlled dielectric thickness. Discuss your stackup requirements with the manufacturer to ensure that they can accommodate your needs. -

What if I need to make changes to my PCB data files after placing the order?

If you need to make changes to your PCB data files after placing the order, contact the manufacturer as soon as possible. Depending on the stage of production, the manufacturer may be able to accommodate your changes, but this may incur additional costs and delay the lead time. In some cases, the manufacturer may need to start the production process from scratch, which can significantly increase the cost and lead time.

Conclusion

Providing complete and accurate PCB data files is essential for ensuring the successful fabrication and assembly of your PCBs. By including the necessary Gerber files, drill files, pick and place file, BOM, stackup, and assembly drawing, you can minimize the risk of errors, delays, and additional costs.

When preparing your PCB data files, take the time to review your design, generate the output files using the correct settings, and verify the files for completeness and accuracy. Provide clear instructions to the manufacturer about your requirements and expectations to ensure that your PCBs are produced according to your specifications.

By following these guidelines and communicating effectively with your PCB manufacturer, you can streamline the PCB ordering process and receive high-quality boards that meet your design requirements.

Leave a Reply